High Quality engineering consultants

Warwickshire’s Most Innovative Engineering Consultancy

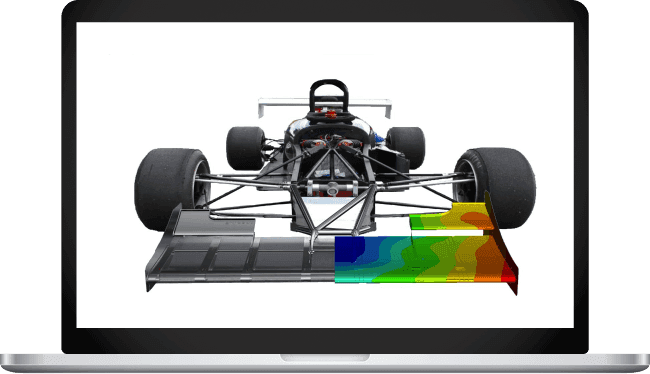

We help to realise your ideas. Our value proposition goes beyond design contributions or analysis reports, it is the knowledge that your product will perform as intended. Simpact have a strong track record of applying CAE services to a range of markets including Automotive, Aerospace, Defence, Industrial, Consumer, Rail and Marine.

Proven Engineering Methods

Mechanical Engineering Approach

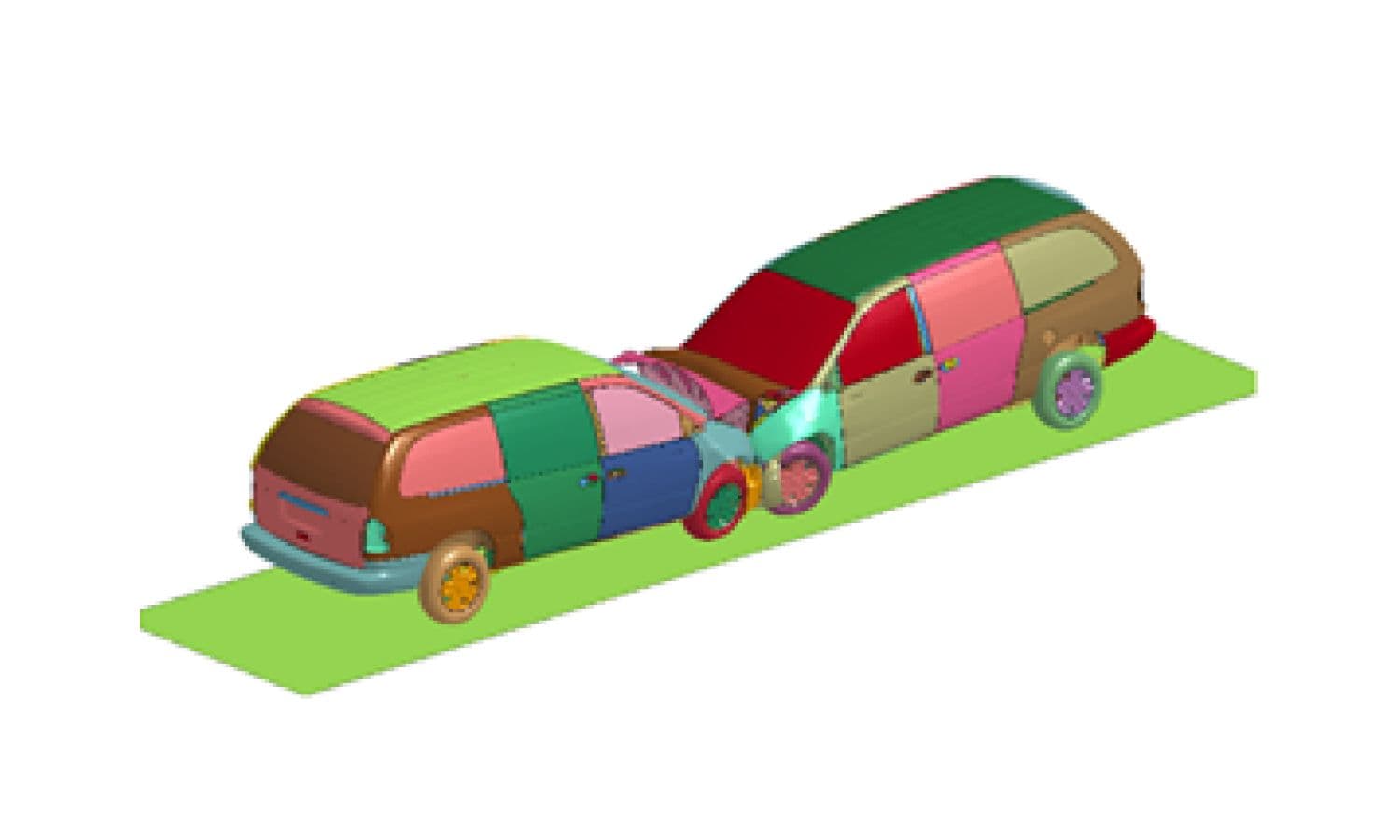

The founders of our dedicated engineering team pioneered the application of CAE tools that revolutionised vehicle safety within the worldwide high volume automotive sector. The high level steps apply universally to de-risk development timescales and budget to make a product a success. We love applying these skills to other markets that have not fully adopted these techniques.

Always starting from basic engineering principles, not a specific piece of software, we will derive the best approach for your new product development. We can help you in the most productive and efficient way.

Our Services

Design Target Specification

Identify and communicate where and how a product will be used, the operational conditions and convert these into quantifiable properties.

Find out more

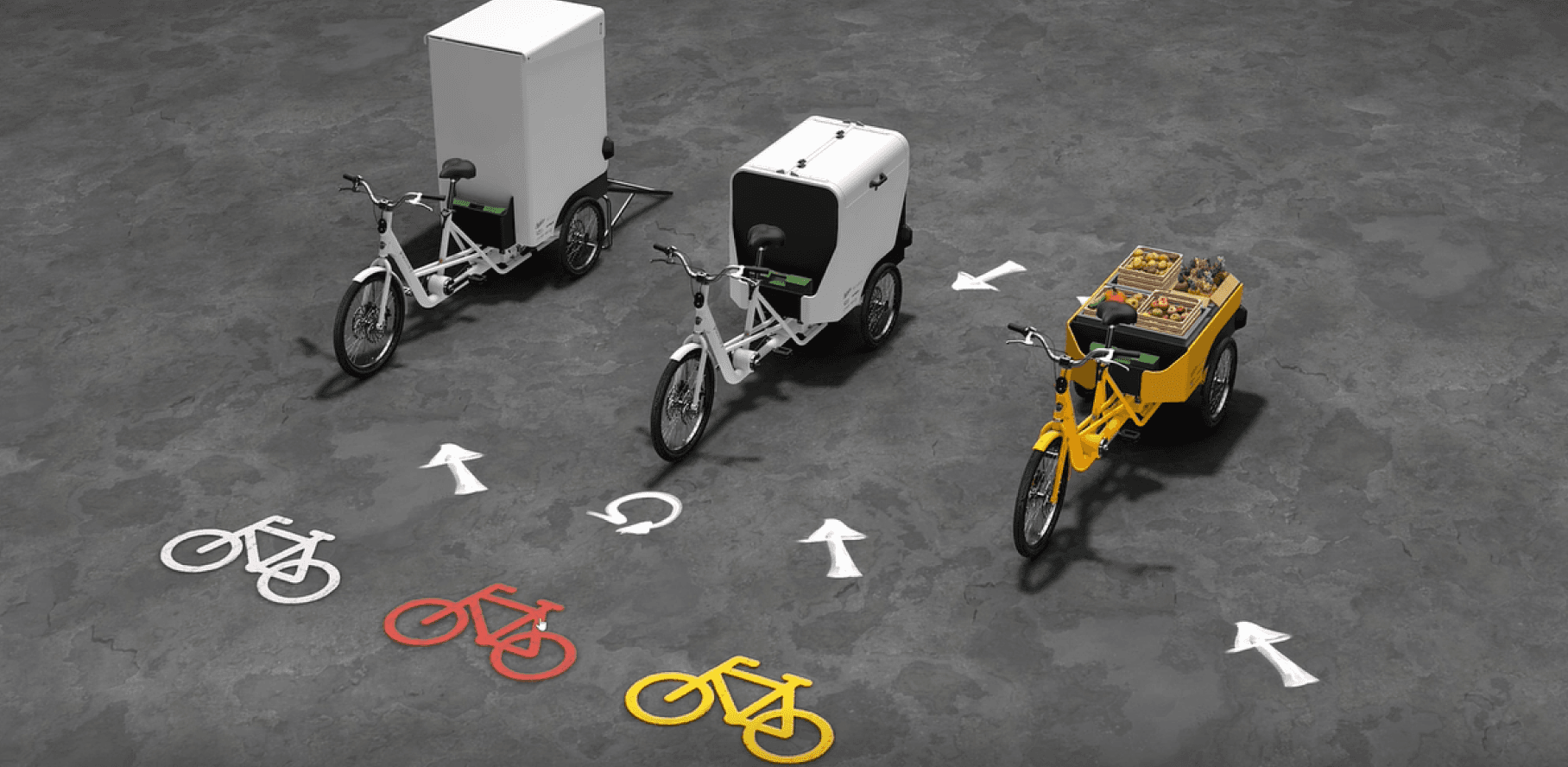

Concept Design

The foundational phase of the creative design process where functional operation is embedded

Find out more

Design Detailing

Verification typically runs in parallel with design. It is the comparison of the system performance to the design targets and it drives design decisions or is used to sign off a design.

Find out more

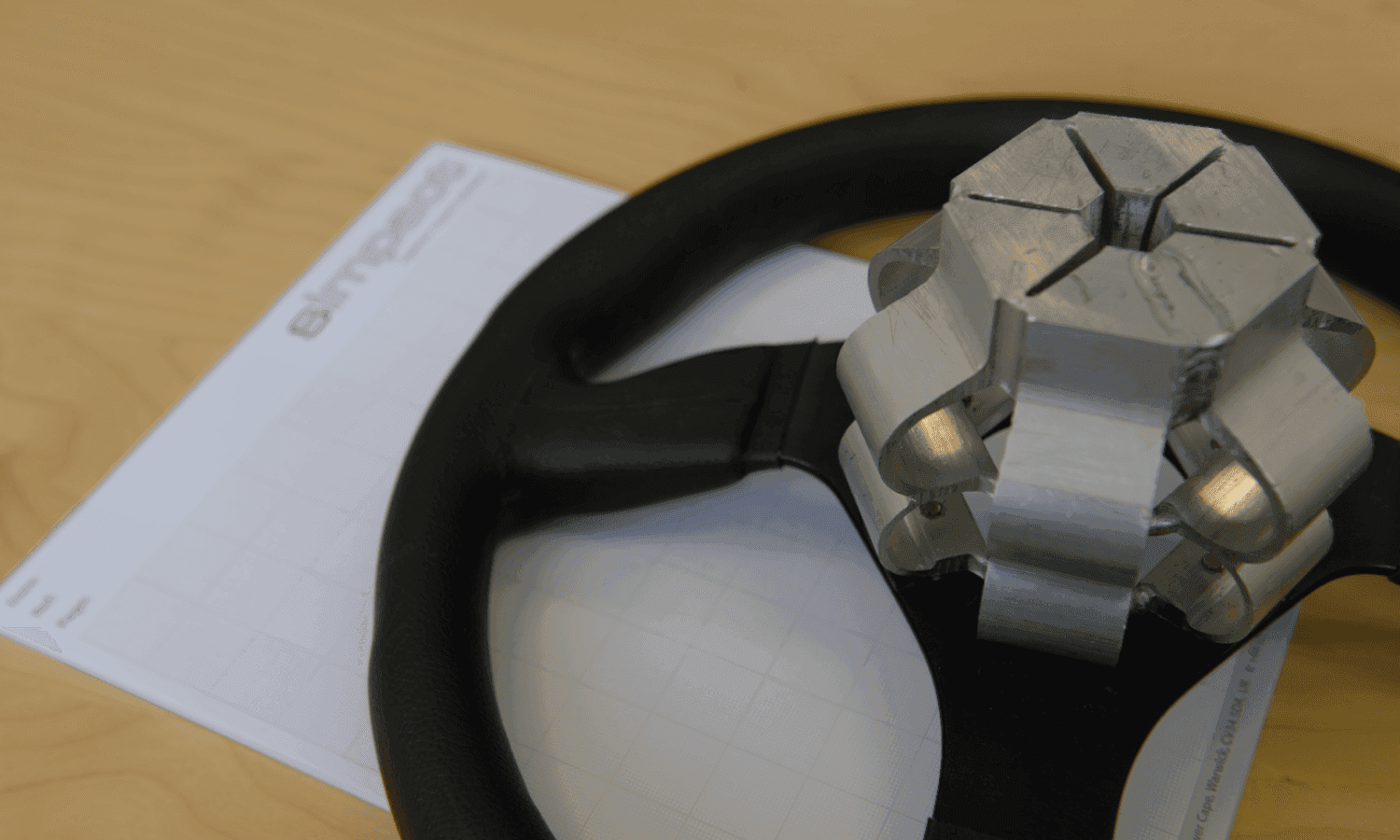

Prototyping and Manufacture

Creating an initial physical representation of a design for review and arranging production.

Find out moreWant to find out more? Get in touch

Contact Simpact today to tell us about your project, and see how we can help.

High Level Engineering Steps

CAE process honed within the high volume automotive sector.

Design Target Specification

Identify and communicate product operational conditions.

Concept Design & Development

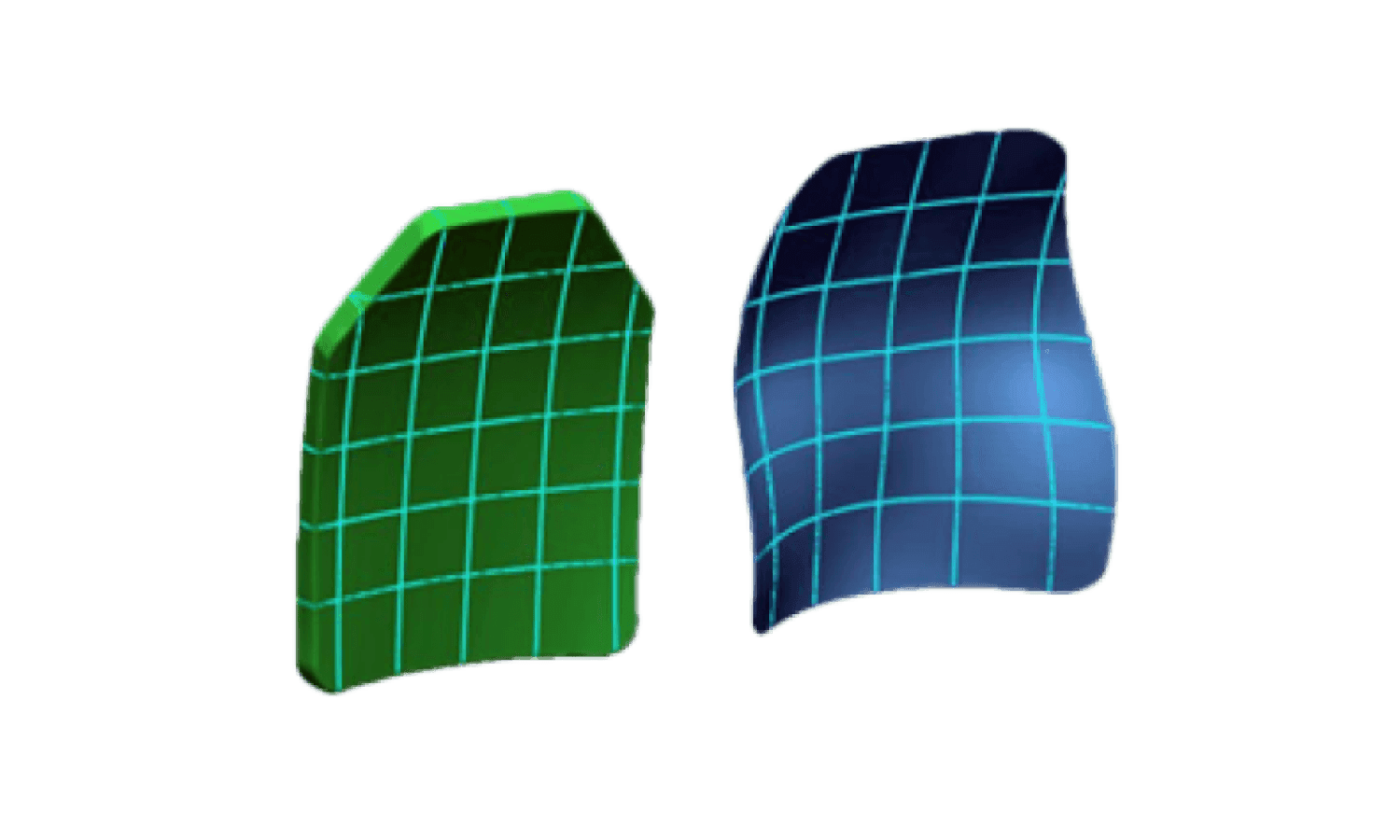

The foundational phase of the creative design process where functional operation is embedded.

Design Detailing

Defining and finalising individual parts and their interfaces.

Physical Prototyping

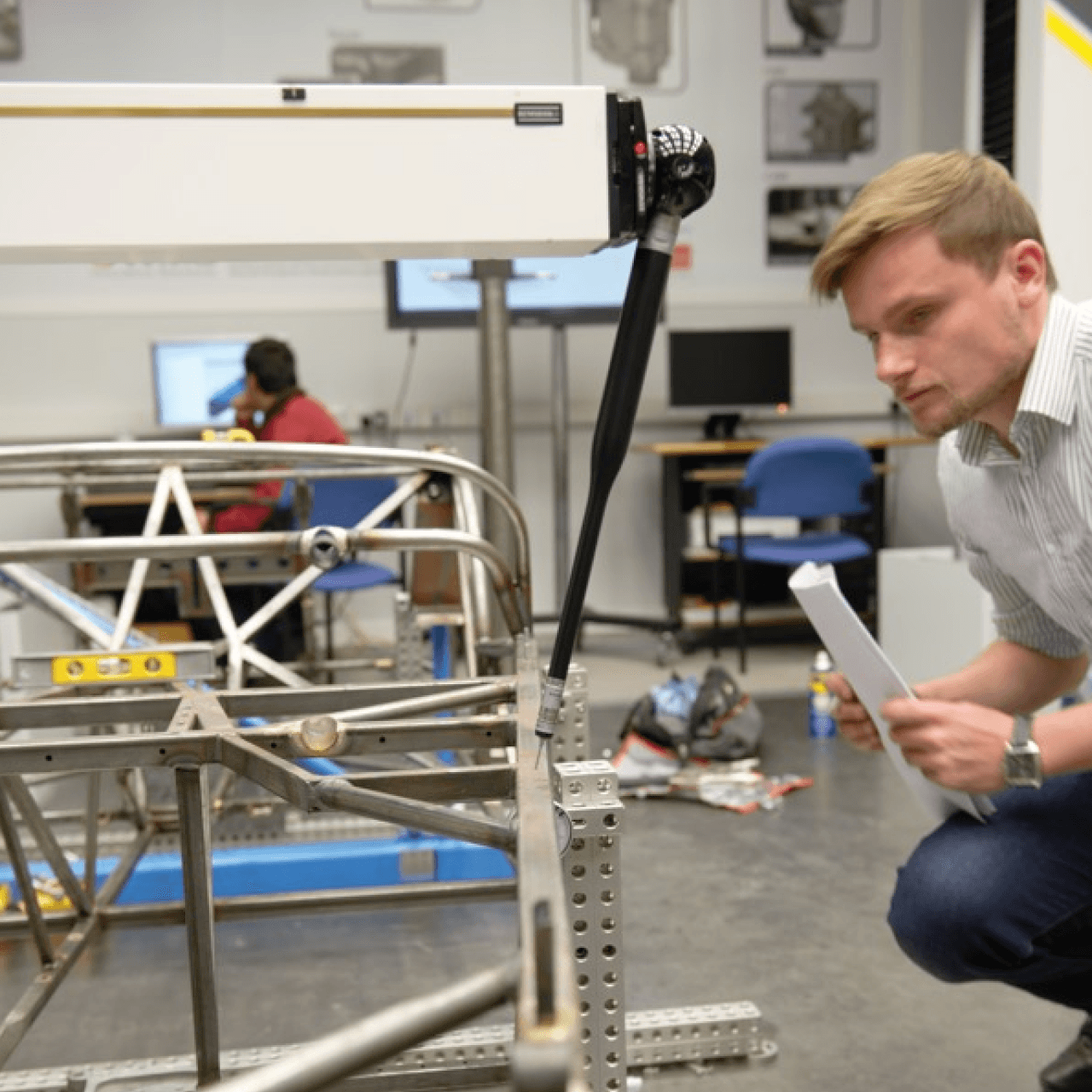

Building for validation or bespoke use (one offs).

Testing

Physical Verification.

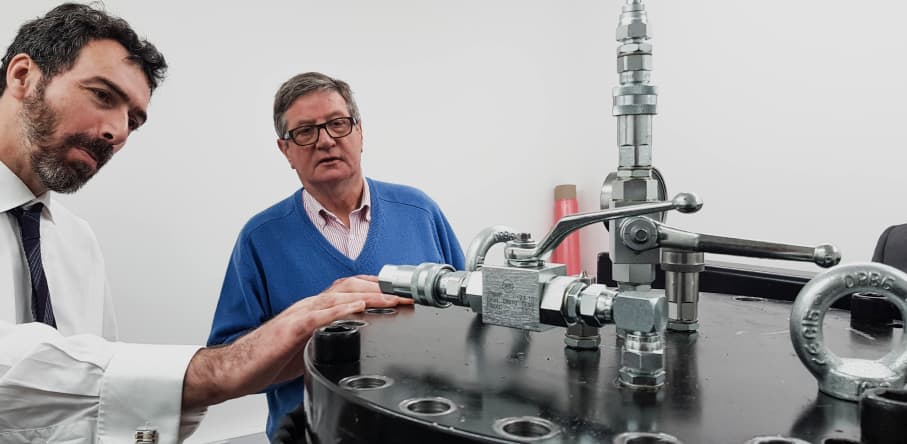

Bespoke Engineering Capabilities

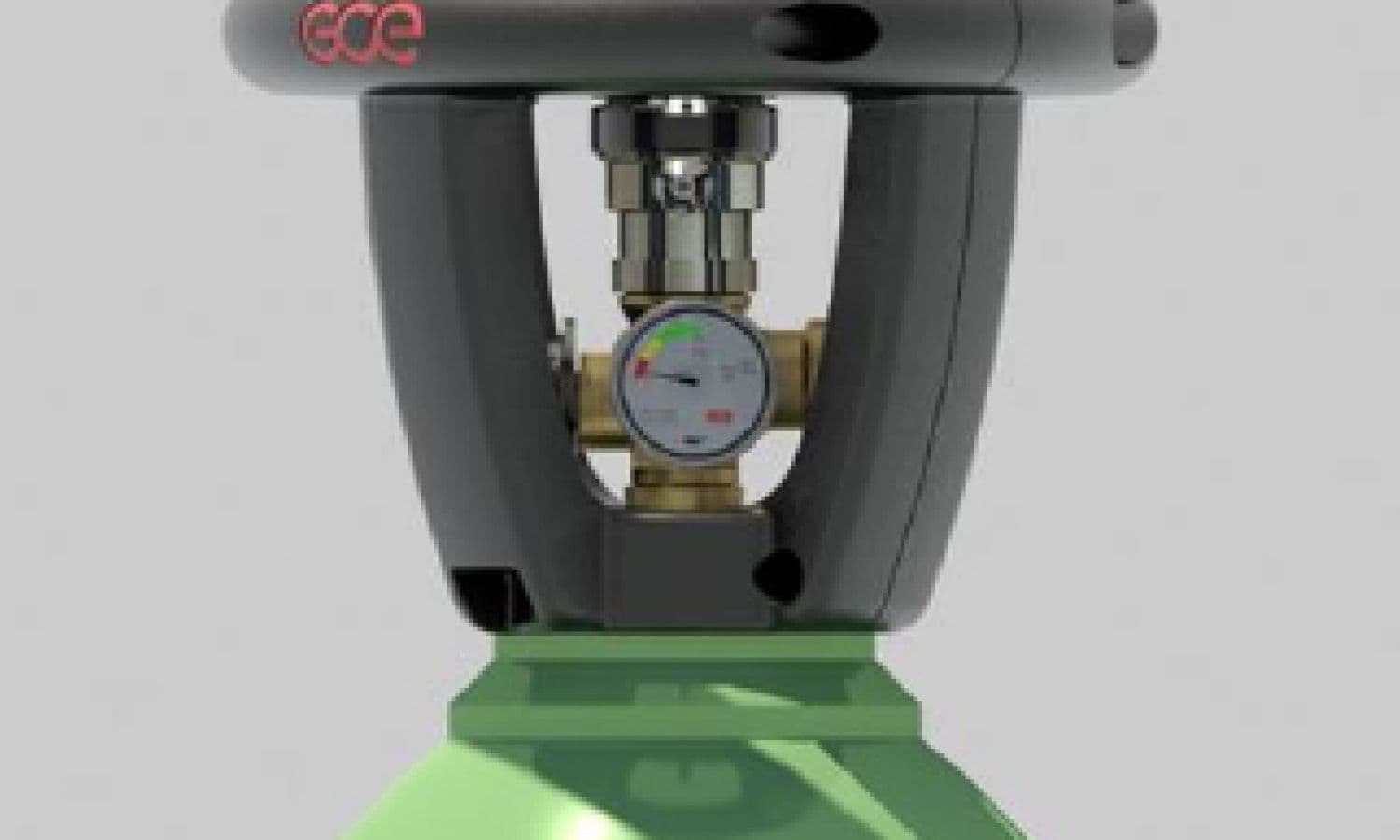

Our Engineering Capabilities span all the technology that you need for the stages of your new product development cycle – from target specification through to certification of the design.

First of all, the engineers mind to interpret our client’s product vision into a functional target set and an engineering roadmap. The capabilities of course include CAD required as input for visualisation, detailed calculations and manufacturing through to things like material characterisation and prototype build. Furthermore, in-house physical testing and data acquisition capability which includes high speed video recording we use for the correlation of CAE models and the verification of impact tests.

Find out moreEngineering Projects

The in-depth knowledge of our team enables Simpact to work across a diverse range of projects and sectors.