Quasi-Static Testing

A common test procedure where a sample to determine the relation between slow elongation and load.

- Home

- CAE Capabilities

- Experimental Test And Data Acquisition

- Quasi-Static Testing

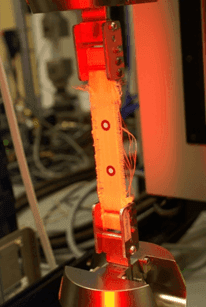

Establishing the basic mechanical properties

Understanding the static response of materials is a fundamental starting point for understanding material and component response to loading. We have our own 30kN Instron Test Frame. If required we make use of a range of tensile test machines including a 100kN and 250kN Instron tensile test machine at the University of Warwick and the University of Leeds respectively. We gain essential information required for the material models which are one of the key ingredients for a robust finite element prediction.

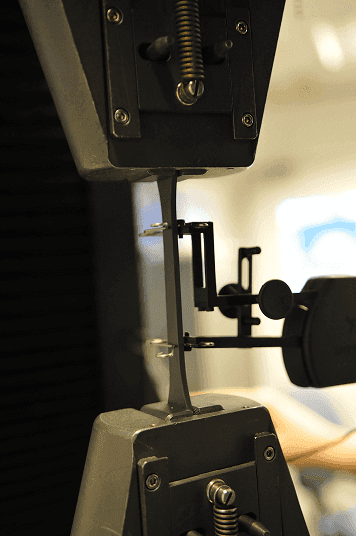

Types of linear extensiometer

For the capture of accurate material test data, either a mechanical or optical linear extensiometer is used to record the actual extension of the sample w.r.t load. This eliminates any slippage in the clamps. Also available with this equipment is an environmental chamber and optical 3D deformation analysis equipment and software which allows us to quantify material performance and carry out digital image correlation (DIC).

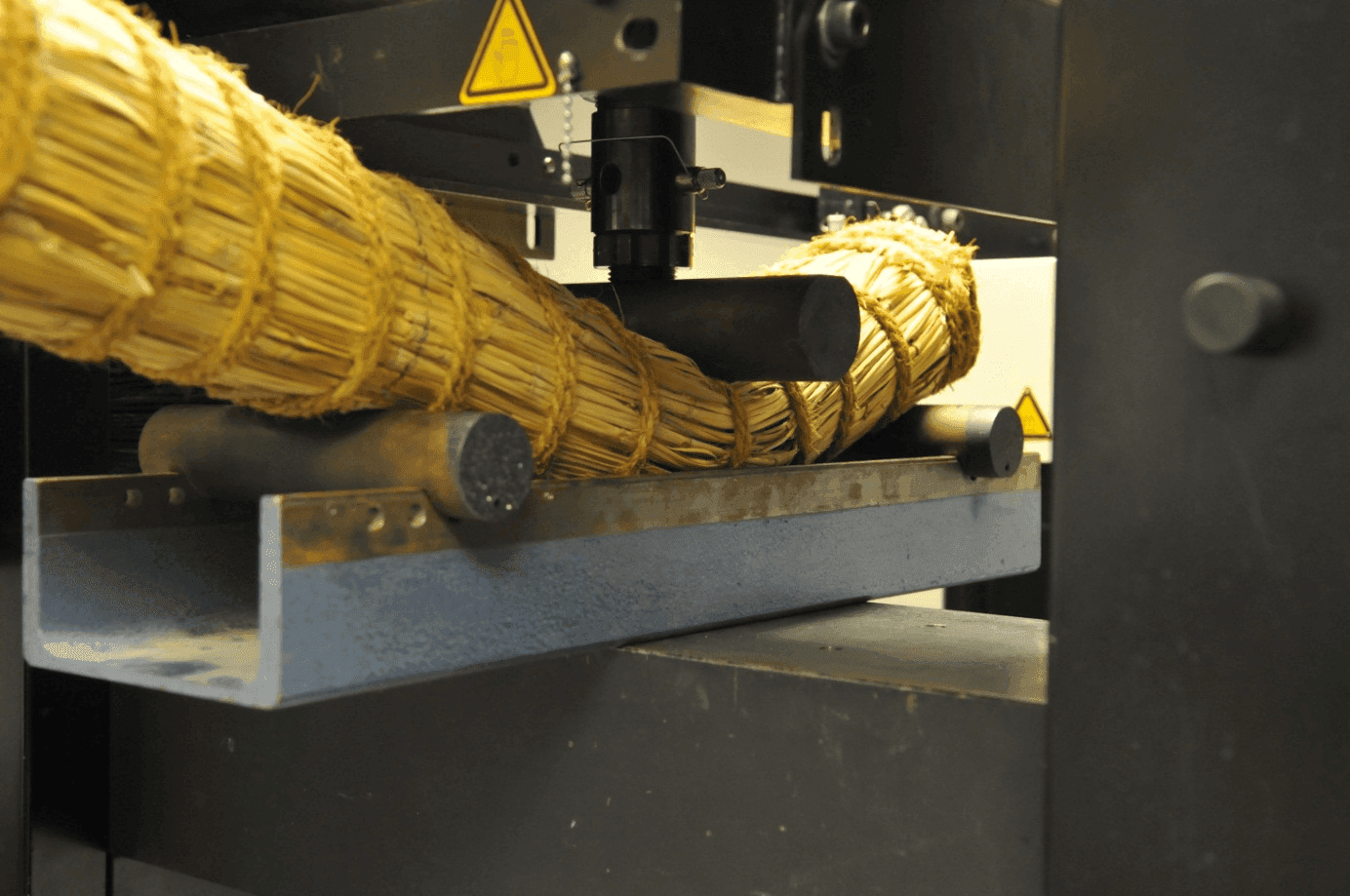

Bespoke actuators

Although the test frames are standard, dependant on the nature of the sample, special actuators or grips can be installed. Simpact have for example designed and developed a set of clamps which are suitable for the quasi-static mechanical testing of ultra-high strength fabrics such as aramids. Structures like these cannot be tested in standard clamping arrangement because of the premature failure that can be induced at the clamps.

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.