Design Verification

Verification typically runs in parallel with design. It is the comparison of the system performance to the design targets and it drives design decisions or is used to sign off a design.

- Home

- Mechanical Engineering Consultancy

- Design Verification

FEA and Physical Testing Services

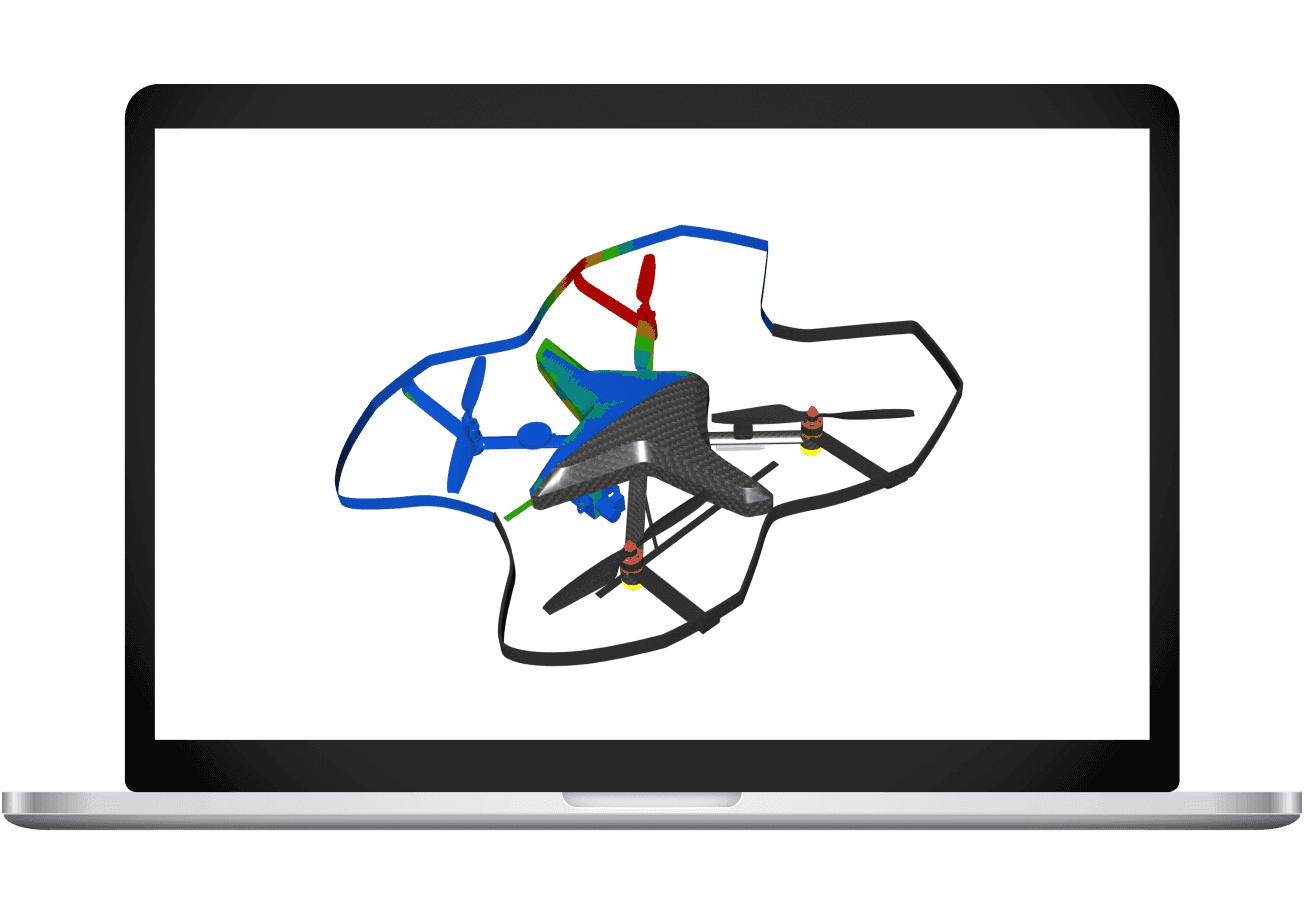

We are experts in deriving test regimes to verify systems, sub-systems or components through cascading of the system requirements. We do this by virtual modelling.

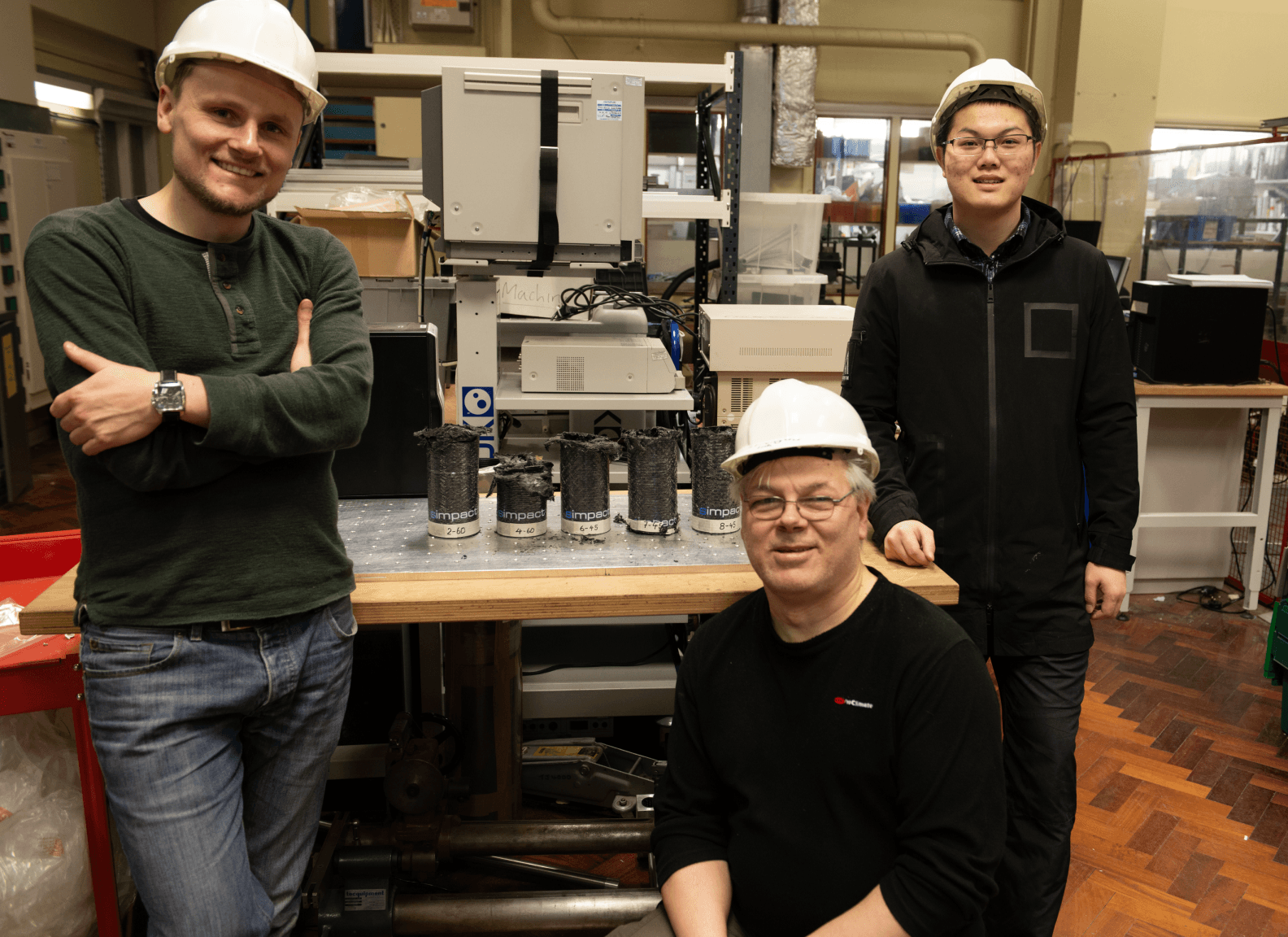

At Simpact we recognise the importance of experimental tests, both as stand-alone tests and for the purpose of numerical correlation. This is the reason why our numerical models can be so accurate — our virtual materials are engineered in such a way to closely match the performance of real-world materials in the actual test conditions.

Thanks to our in-house facilities and partnerships, we always offer our customers the appropriate approach, be it a full-scale blast analysis or a quasi-static tensile experiment.

Bespoke Rigs, CAE and Finite Element Analysis Capabilities

Simpact have a wide range of experimental and numerical techniques at their disposal including:

Engineering Calculations

Up front analysis to obtain the perfect balance for your design

Experimental Testing

For materials evaluation and characterisation, model correlation and certification

CAD & 3D Visualisation

To define designs at a technical level but also Virtual Reality scenarios for assessments, training and marketing your products or ideas

Digital Image Correlation (DIC)

Dynamic surface scanning to measure motion and deformations

3D Capture

A range of non-destructive 3D capture technologies for obtaining accurate geometry for both large and small items

Why Choose Simpact?

Pure engineering consultancy is at the heart of Simpact’s culture. We deliver projects to an exceptionally high standard resulting in the best possible impact for our customers' products. Unlike the CAE software vendors, we are completely focussed on your needs and we are not tied to the constraints of a particular CAE software tool, giving our customers the nimble support that they need and benefit from the most.

Our staff have unmatched experience and technical skills and excel in solving some of the most challenging engineering problems that exist. We have access to a wide range of state-of-the-art CAE tools, enabling us to adapt and transfer skills across a range of diverse markets.

More about Simpact

Additional Services

Simpact’s expertise can be applied throughout the product life cycle, from initial designs, to manufacture.