Prototype Engineering and Manufacturing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim.

Prototype Development and Manufacturing Services

To produce prototypes you can’t rely on the same methods as for series production and vice versa. For prototyping, tooling costs cannot be amortised over a large number of units and timescales are short. Consequently, material properties can vary between prototype and series product. Simpact understands those differences and can select the appropriate method and where necessary tailor the design accordingly.

Over the years Simpact has helped many customers and have built a strong network of production facilities including sheet metal fabricators, machinists as well as 3D printing or other additive manufacturing techniques. Our team has a wealth of experience in assembling complex systems and liaising with suppliers.

Design Target Specification Tools

Simpact have a wide range of bespoke CAE, prototyping and physical testing tools including:

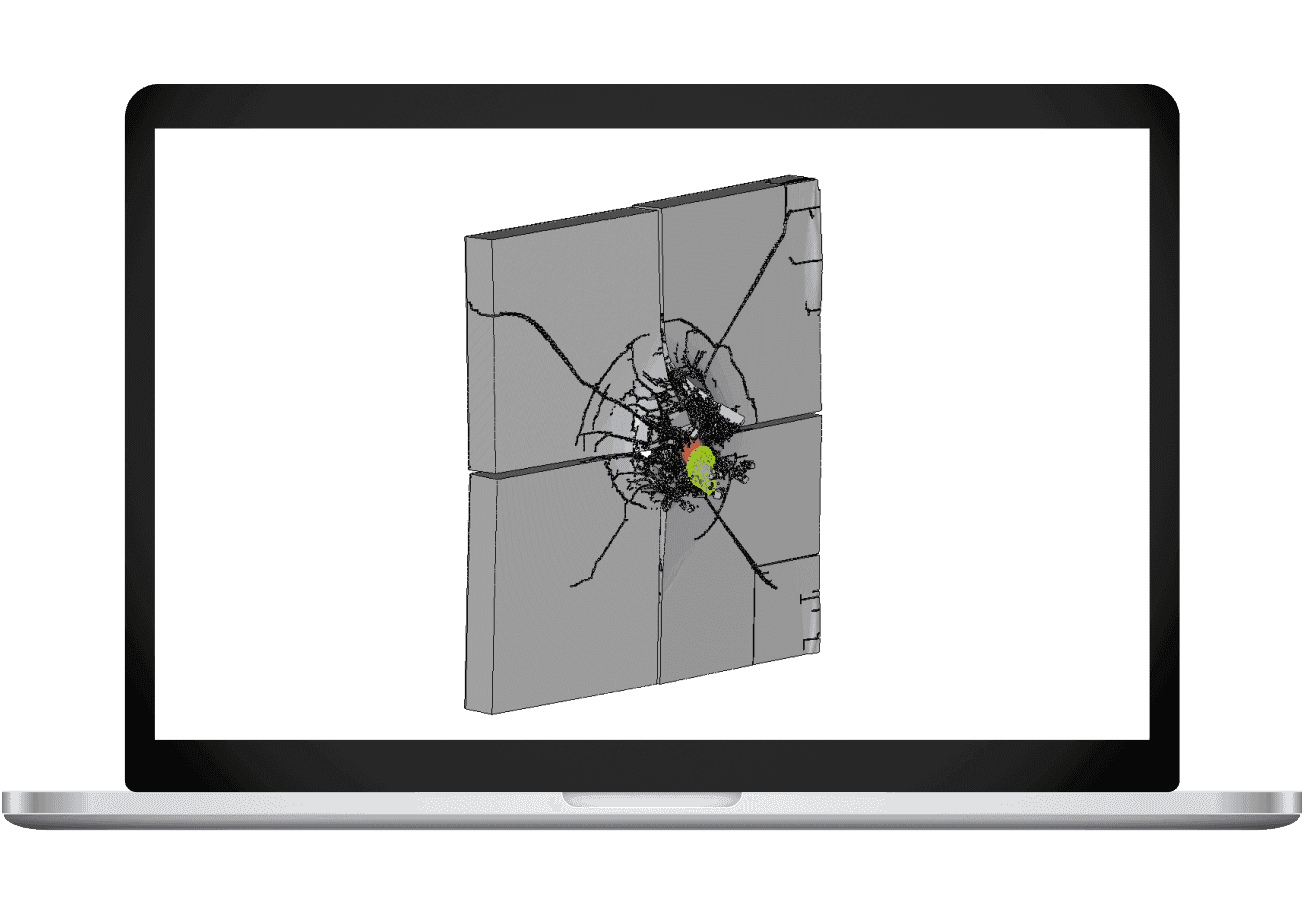

Numerical Simulation and HPC

Up front analysis to obtain the perfect balance for your design

Experimental Testing

For materials evaluation and characterisation, model correlation and certification

CAD & 3D Visualisation

CAD Design and generating the best visual impact for marketing your products

Digital Image Correlation (DIC)

An essential CAE tool for new product design and development

3D Capture

A range of non-destructive 3D capture technologies for obtaining accurate geometry for both large and small items

Why Choose Simpact?

Pure engineering consultancy is at the heart of Simpact’s culture. We deliver projects to an exceptionally high standard resulting in the best possible impact for our customers' products. Unlike the CAE software vendors, we are completely focussed on your needs and we are not tied to the constraints of a particular CAE software tool, giving our customers the nimble support that they need and benefit from the most.

Our staff have unmatched experience and technical skills and excel in solving some of the most challenging engineering problems that exist. We have access to a wide range of state-of-the-art CAE tools, enabling us to adapt and transfer skills across a range of diverse markets.

More about Simpact

Our Products

At the heart of our business plan is the design, development and manufacture of impact related products founded on our own IP. We manufacture these under licence in partnership with a suitable manufacturer.

Some examples of products we produced can be found here. We welcome enquiries from manufacturing partners wishing to combine their respective strengths with ours, and together develop the highly innovative products of tomorrow.

Find out moreAdditional Services

Simpact’s expertise can be applied throughout the product life cycle, from initial designs, to manufacture.